Software development by Maidl Tunnelconsultants

Maidl - PROCON II

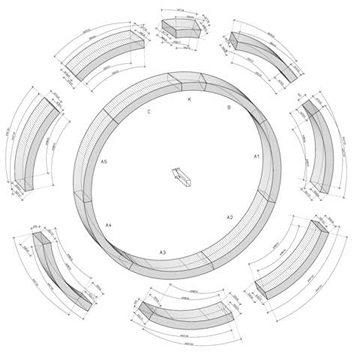

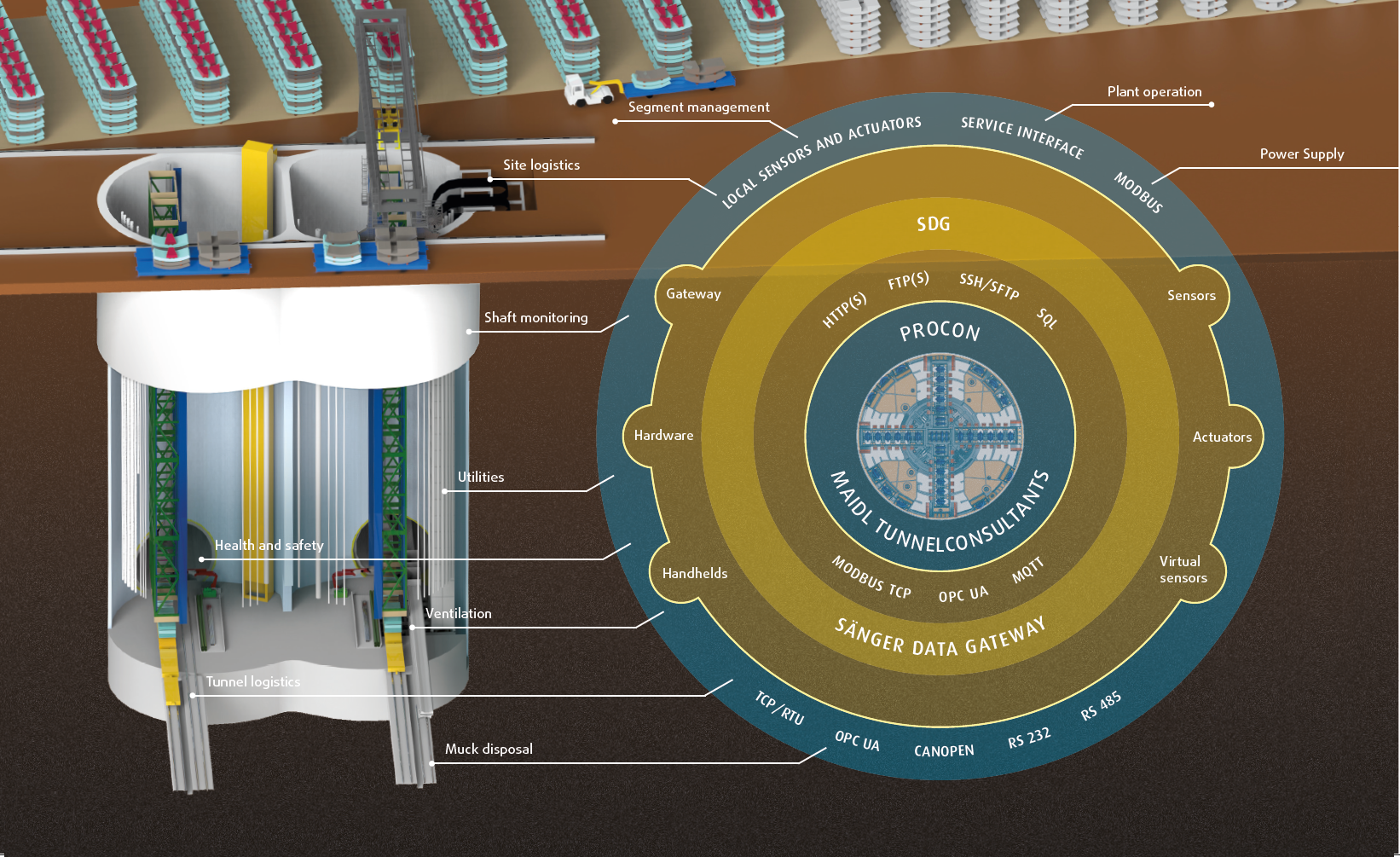

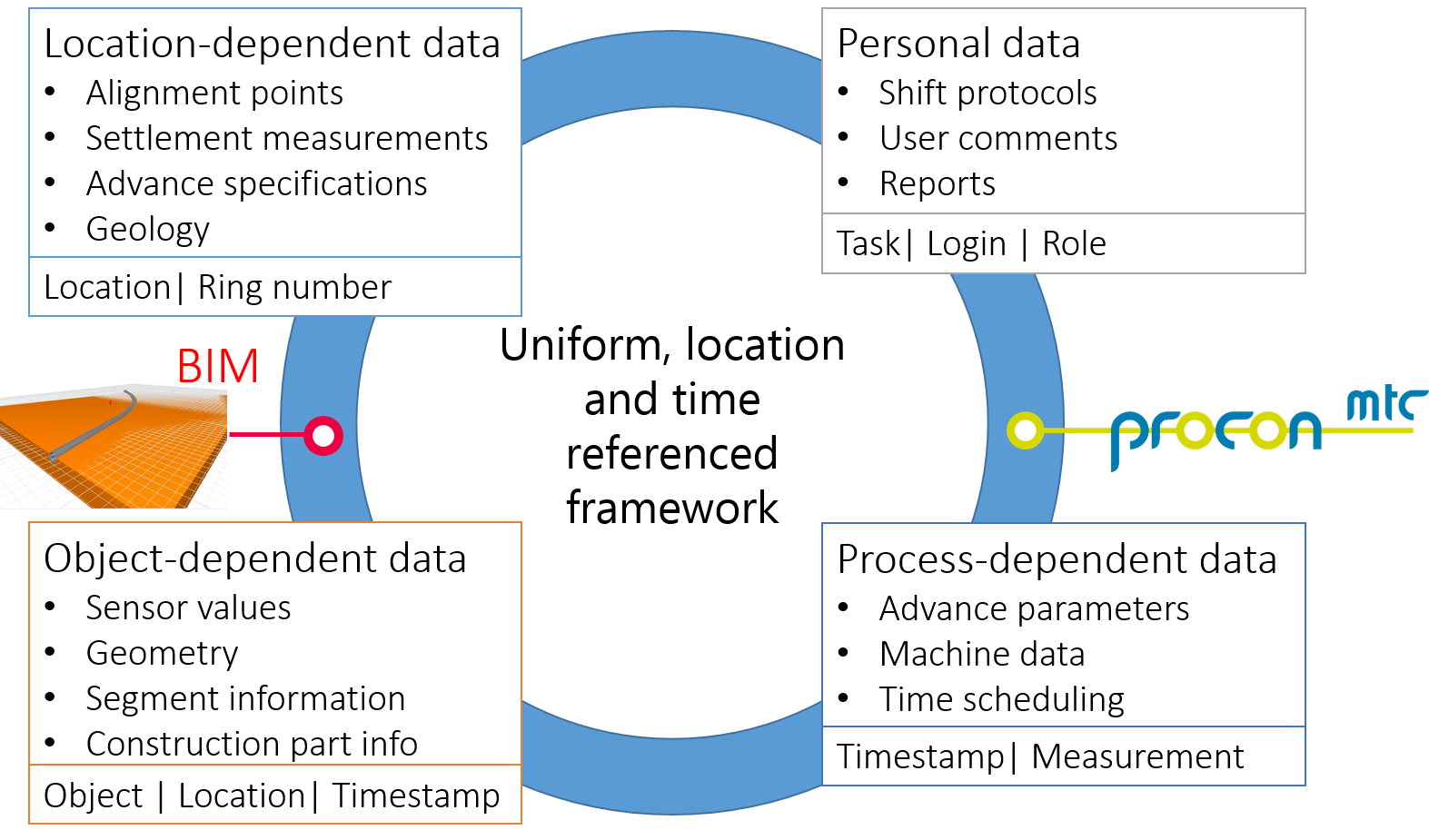

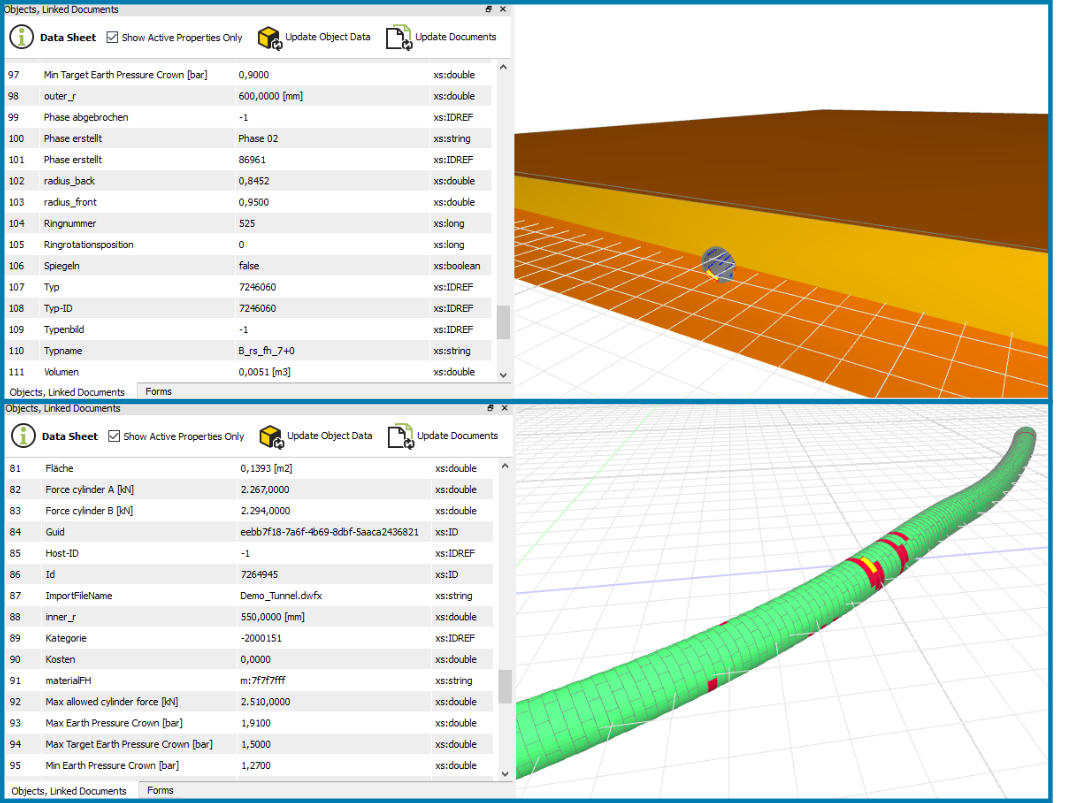

Developed by MTC, PROCON II is used for the acquisition and

visualization of machine and monitoring data, design parameters,

geotechnical and cutter tool information as well as alarm messages

and shift documentation. Our digitized know-how of more than 200

reference projects with a total number of more than 600 kilometers

of tunnel advance is employed in the optimization of tunneling

processes.

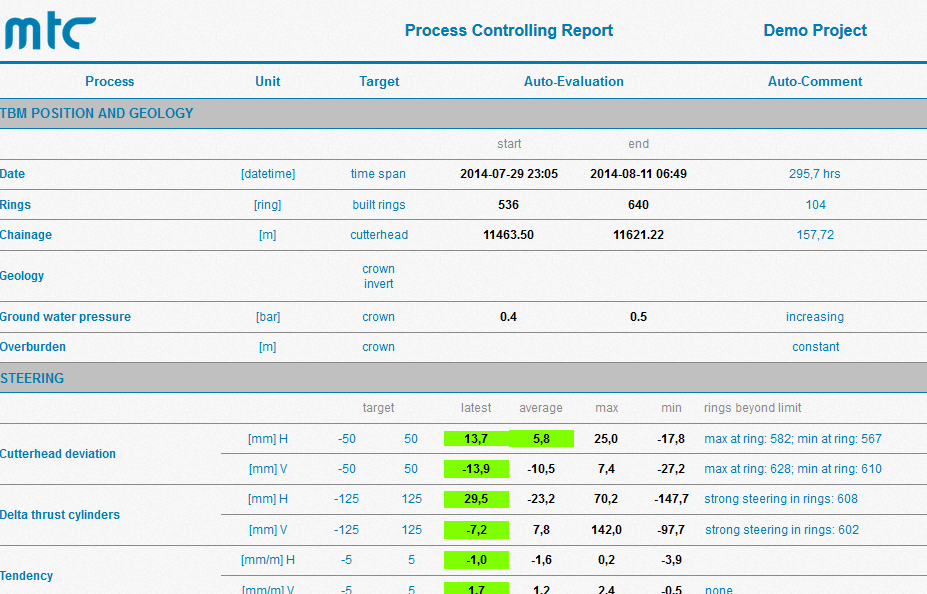

A comparative variance comparison, which involves all

construction processes, is performed with our PROCON II software

on a technical, schedule and cost basis in real time as the

excavation proceeds. All relevant project information (design

parameters, target and actual values) is categorized in a

centralized database, where the information is registered and

analyzed against a knowledge base.

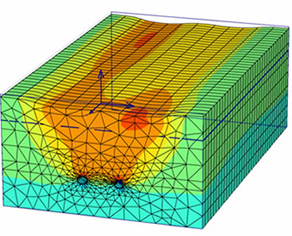

The entire know-how acquired during planning, in

particular geotechnical soil investigation and calculations, is

opposed to the actual construction process information. Knowledge

gained from this process can be provided to the people involved in

the project in real time. This allows identifying critical

situations and apply countermeasures in time.

For new projects we provide prognosis models for the

estimation of the performance, costs and risks.